Operation Principle:

Capacitive touch panel works through body's current induction. When finger is on or close to touch panel surface, due to body electric field, the user and touch panel surface forms one coupling capacitance.

For high frequency current, capacitance is direct conductor, then fingers suck a small current from the contact point, through amplifying and accurately calculating this current signal,

Finally the controller works out the touch point position

Projected Capacitive Touch Screen Technology:

Projected Capacitive Technology permits more accurate and flexible operation by etching the conductive layer on the touch screen.

Projected Capacitive Touch Screen uses multiple layers of glass or film with optical bonding in assembly process.

Cover lens is usually made by tempered glass which can stand against shock and impact.

Projected Capacitive touch panels are embedded with high performance IC and users can enlarge, shrink, rotate, flip and drag pages easily due to the multi-touch gesture support (multi touch screen).

| Comparison between Capacitive Touch Panel and Resistive Touch Panel |

| Capacitive Touch Panel | Resistive Touch Panel |

| Touch (no pressure needed) | Press (pressure activated) |

| No calibration required | Calibration required (resistance drift on film) |

| Better Durability, No significant aging | Display turns white when aging |

| Handles high temperature | Film breaks down at high temperature |

| Better Transparency, less optical power needed | Low transmission |

| Can be vandal-proof (thick glass/plastic) | Easily damaged (thin top layer) |

| Scratch Resistant (with glass) | Prone to scratch |

| Stylus not a must | Need stylus, easy to lose |

Product Specification:

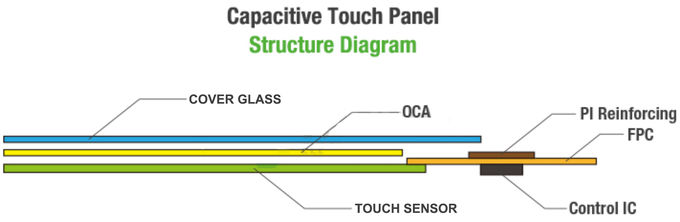

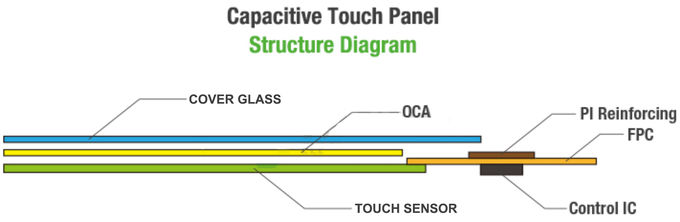

The structures explanation:

* P G=PET Glass (cover lens is PET and touch sensor is glass).

* G G=Glass Glass (cover lens is glass and touch sensor is glass).

* G F/F=Glass Film Film (cover lens is glass and touch sensor is film film).

* CG= Cover Glass, OD= Outside Dimension, VA= Viewing Area.

Custom Projected Capacitive Touch Screen:

Our capacitive touch panel design can be suitable for housing design from the customers to cover their lens or replace the physical buttons on its original module.

we are also capable of doing the customized shape needed to suit for customer's mechanical design.

With the assistance of the simulation software, equipment with high accuracy and simplifying assembly process, we are capable of making the sample in shorter period and with lower development charge.

| Lens’s Features ►Shape: Irregular and hole ►Color: Silk printing, Logo ►Glass brand: AGC, Corning, CSG, ETC ►Treatments: AG, AR, AF, Anti-explosion ►Thickness: 0.55mm, 0.7mm, 1.0mm, 1.1mm, 1.8mm, 2.0mm, 3.0mm, 4.0mm

|

Sensor Features

►Sensor material: Glass, Film, Film / Film ►Thickness:0.125mm,0.4mm,0.55mm,0.7mm,1.1mm ►FPC: Shape design optional ►IC: Focaltech, Goodix, Cypress, EETI ►Interface: IIC, USB, RS232, SPI

|

Assembly

►Optical Bonding with OCA

►Double faced adhesive tape |

Product Application:

| Telecommunication Devices | Telephone, interphone, watch, tablet PC, radio, etc |

| Consumer Products | Camera, DVD player, toy, Cell Phone, game player, etc |

| Technical Equipment | Elevator controller, Industrial machine, etc |

| Office Automation | Printer, scanner, attendance machine, fax machine, etc |

| Home Appliances | Air-condition display, refrigerator, electric cooker, video doorbell, etc |

| Automobile | GPS, video player, speedometer, audio broadcast, etc |

| IT Products | Camera, handheld digital video, projector, media play, tablet PC, etc |

| Medical Equipment | Ultrasound machine, therapeutic equipment Blood pressure meter, etc |

Our Advantage:

| Rich experience | Good knowledge of the displays market to put together solutions that add value and provide a unique proposition for the client |

| Advanced Equipment | Full automatic FPC&IC bonding machine, film attaching machine, CNC machine, polish machine etc advance production equipment ensure product quality |

| Quality Assurance | Advance inspection instrument and equipment to ensure 100% inspection for each and every piece before shipment |

| Fast response | Quickly realize your customized ideas, and have a sample ready in short time |

| Low MOQ | Depends on product |

| Stable supply | 1~10 years supply period |

| Extensive range | Providing complete solution from Mono to Color LCD module, Optical bonding between display to cover glass as well as cover glass to touch screen |

| Large production capacity | Operation capacity 2KK monthly |

| Quality guarantee | RoHS compliant |

| Management | ISO 9001:2008, ISO 14001:2004 |

FAQ:

Q: What is the MOQ?

A: It depends on different products. Please keep in touch with sales to confirm the MOQ.

Q: What about the delivery time?

A: Ready-made Sample: within 1 week

Custom Sample: 1~2 weeks

Mass production: 4-6 weeks

Q: Does your product have any warranty?

A: Yes, we offer 12 months warranty for our products.

Q: What's your payment method?

A: For samples: payment in advance.

For mass production: 30% deposit and 70% balance before shipment.

Q: What's your shipping method?

A: We provide comprehensive shipping methods.

For small quantity orders we ship by UPS Air-Express, or DHL/FEDEX/TNT/ EMS Express service, it is safe and fast.

For large quantity orders we ship by buyer's cargo agent in China,

we can also ship by Air transportation or sea transportation.

Q: Do you offer custom solution?

A: Yes, we can offer custom solution if standard products couldn't meet buyer' requirements.

Related Products:

-

RXC-PG10104-01

-

RXC-PG08002-01

-

RXC-PG07038A-1.0

-

RXC-PG07018-01

-

RXC-GG07012-01

-

RXC-GG07004-01

-

RXC-GG05023-01

-

RXC-GG05022-01